Development

- HOME

- Development

CHARMANT Spirit

CHARMANT is an innovator in the field of titanium surgical instruments, dedicated to making a lasting contribution to society's fundamental well-being through revolutionary technology. Our products are the culmination of newly-developed titanium processing technology, cutting-edge laser micro welding capabilities and a comprehensive understanding of state-of-the-art materials.

Each instrument is thoughtfully designed by our Japan-based team of experts, in conjunction with leading surgeons, to give medical professionals the degree of precision and accuracy required to advance MIS capabilities.

CHARMANT is dedicated to providing people hope for a comfortable, healthier and happy life through the development of innovative medical technologies.

“Charmant Group" is renowned worldwide as a premier company in the global eyewear industry for their groundbreaking Research and Development of new technologies for the optical market. Unparalleled expertise in top-quality production and breakthrough technologies, dedication to customer service and a commitment to excellence set Charmant Group apart in their field. The Group expanded their expertise of new material development in medical field.

CHARMANT Surgical Instruments

CHARMANT surgical instruments are designed to increase tactile sensation for the surgeon for optimum control and functionality.

Instruments incorporate multiple titanium alloys and exclusive special alloy, fused together to provide lightweight strength, springiness and durability.

Surgeon input is an integral part of CHARMANT's development process for instruments that are ergonomic, innovative and practical.

Our team of experts manufacture and hand-finish each instrument at the micro level to ensure excellence and satisfaction.

Benefit of Titanium

- Non corrosive

- Lightweight and strong

- Non magnetic

- Biocompatible

The most appropriate kind is selected from various titanium alloys for CHARMANT instruments and exclusive special alloy at the distal parts of scissors maximize the performance of the products.

Constellation of Titanium

| Commonly called | Composition | sp.gr. | Elasticity | Feature | Uses |

|---|---|---|---|---|---|

| Pure Titanium | Titanium | 4.5 | 0.8% | lighteight corrosion free nickel free |

Aircraft parts Fashion accessory |

| Beta Titanium | Titanium vanadium aluminum |

4.7 | 1.4% | lighteight heat resistant highly elastic |

Golf clubs |

| Memory Titanium Alloy | nickel Titanium |

6.5 | 7.5% | memory function hyper elastic |

Guide wires cell phone parts |

| Flexible Titanium Alloy | Titanium zirconium niobium |

5.6 | 1.6% | biocompatible highly elastic |

Medical device (joint prostdesis,) (Endovascular device) |

| (Charmant exclusive) | Titanium zirconium niobiumなど |

5.4 | 4.0% | highly elastic memory function Nickel free Biocompatible |

*Exclusive for Charmant branded eyewear |

- *Multiple kinds of beta titanium exist.

- *Elastic ranges vary under different conditions.

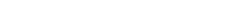

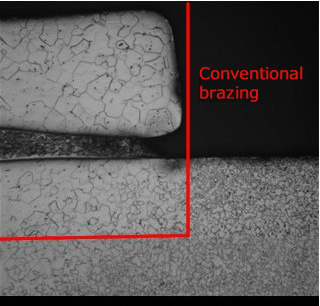

Charmant’s laser micro welding technology successfully eliminates deterioration of material or mechanical characteristics cased by thermal effect in conventional brazing.

Laser micro welding vs Conventional brazing

Conventional brazing

- Large area is thermal affected to cause deterioration.

- Limits the dimensions for quality welding

- Likely to cause scratches and deformatons

Laser micro welding

- Minimal thermal affect causes little degeneration of strength

- Accurate welding in microscopic dimensions

- No scratches and deformations

CHARMANT instruments are As Laser micro welding, which requires rather accurate finish of components microscopic oimeusions .

Quality management system

Charmant’s long established quality management and control system assure the users reliable and stable quality.

- Every step in the production process is designed to assure quality.

- Trained and qualified specialists strictly execute the processes to meet required specification.

- Strict in-process inspections and final verification are undertaken.

- Quantified quality guideline for parts and assembled products apply.

- Meticulous inspection are made throughout the production process.